The bonding process:

In most cases, materials are bonded with the use of a suitable water-based resin. However, we are also able to do bonding work using hot-melt film.

Base material

●Natural material (weave / knitting)

●Synthetic material (weave / knitting)

●various films

●Nonwoven fabric

●Paper

●Cotton

●Urethane foam

●Artificial leather

●Rubber Sheet

●Synthetic material (weave / knitting)

●various films

●Nonwoven fabric

●Paper

●Cotton

●Urethane foam

●Artificial leather

●Rubber Sheet

Adhesion resin

Water system

●Acrylic

●Urethane

●EVA

●Acrylic

●Urethane

●EVA

Hot melt film

●TPU

●TPU

Base material

●Natural material (weave / knitting)

●Synthetic material (weave / knitting)

●various films

●Nonwoven fabric

●Paper

●Cotton

●Urethane foam

●Artificial leather

●Rubber Sheet

●Synthetic material (weave / knitting)

●various films

●Nonwoven fabric

●Paper

●Cotton

●Urethane foam

●Artificial leather

●Rubber Sheet

With bonding, a wide variety of adhesive resins allows for the processing of many different substrates.

It also yields a particularly soft texture and excellent breathability.

It also yields a particularly soft texture and excellent breathability.

Processing content list

Industrial materials

| Vehicle seat durable adhesion | breathability |

|---|---|

| Filter sheet Durable adhesion | breathability / deodorant |

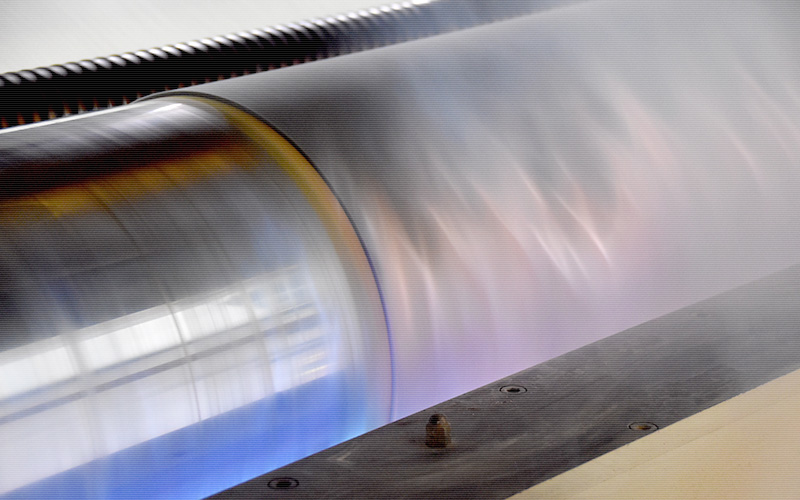

Frame laminating step

It is a method of gluing the surface of urethane foam with fire, bonding the cloth to where urethane has melted, and bonding.

Base material

●Urethane foam

●Tricot

●Textiles

●Artificial leather

●Nonwoven fabric

●Tricot

●Textiles

●Artificial leather

●Nonwoven fabric

effect

●Releasability

●Cushioning

●Cushioning

The special feature of flame lamination is that it combines the ability to give the product a great appearance that has a feeling of three-dimensionality with the fact that it does not reduce the elasticity of the material.